The top surface of scale body is the part where the truck tires roll. Steel structure plate or concrete structure surface,both of them are designed upon the same standards,therefore they can perform the same weighing functions theoretically. However some discrepancies of two structures are still existed in practical applications,so cautious selection is beneficial to user’s actual applications.

Comparison of Steel Plate and Concrete Surface

| Surface with steel structure | Surface with concrete structure(pouring on site) | |

| Installation time | one day | about 30days for concrete maintenance |

| Shipping weight | light | heavy(after pouring) |

| Anti-corrosion | normal | better |

| Skid resistance | slippery in rainy days | good anti-slip effect in rainy days |

| Point loading | not recommended | available |

| Maintenance | good | good(large capacity Jack recommended for easy operation) |

| Service life | good | good |

| Total cost | good | good |

Steel Plate

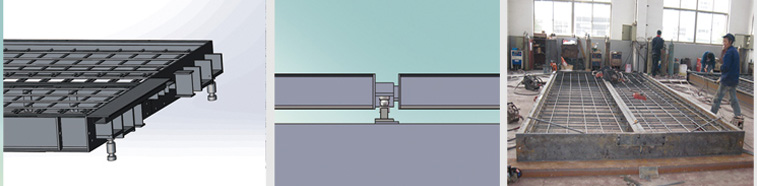

Steel plate with the sealed structure is manufactured in factory,composed of main beam and structural parts by welding procedure. And the plate can be used immediately once it is completely installed. Because it is assembled strictly and verified in factory,and only the least influence on the overall performance will be generated.

Steel plate can adopt checked plate as the driving surface,which helps to increase thr friction force when surface is wet and rainy. Some users tend to choose concrete surface which has better skidproof performance in rainy or snowy days. In most cases,checked plate has the equal skidproof effect with concrete surface. But actually people are more inclined to let truck drive on concrete surface in rainy days rather than on steel pate.

Concrete Surface

The concrete weighing platform is formed by means of filling the concrete into the steel structure frame during installation. Truck scale supplier provides all structural parts and steel bars,and the third-part contractor pours concrete that meets the specifications of the truck scale,usually pouring work is completely at the customer’s site. Concrete weighing platform needs at least 30 days for maintenance before it is officially put into use.

When considering the total cost of investment in concrete truck scale,also carefully confirming whether the concrete cost and the labor cost of pouring concrete are included. Due to the weight of concrete weighing platform is much heavier than the weighg of steel structure,in consequence,a stronger foundation is needed and this will increase the cost,then comparing the prices between concrete weighing platform and steel weighing platform,they are almost the same.

Some truck scale provides concrete weighing platforms that are poured in the factory. Although this reduces the time required for concrete maintenance on site,but concrete weighing platform is easily damaged during transportation. In addition,after pouring,the concrete platform is so heavy,it will cause more expensive shipping cost,sometimes two trucks are needed instead of one,they also need more cranes to install. So if you consider this way,you need to make sure that you’re familiar with the impact of the project cost caused by above factors.

In short, the advantages of concrete weighing platform with small capacity are:

1. Weighing platform is heavy,usually the weight is 4 times as much as the weight of steel plate platform,consequently it can better resist the longitudinal impact generated by truck’s accelerated speed when driving through the weighing platform.

2. Concrete weighing platform has the surface with uniform and equal strength that can be used in semi-trailer canning applications. The semi-trailer can be supported by carriage brackets at any position on the platform surface when loading on the platform,the strength of the surface is high and uniform,it can withstand such high local loads without local deformation of the surface.

3. Corrosion resistance is another factor that needs to be considered. For some corrosive media,steel plate is a better choice;and for other corrosive media,concrete plateform is also a good option. Truck scale’s supplier can make some recommendations based on users’ applications.