We wish purchase accurate and reliable truck scales to efficiently complete weighing tasks,then what information should we need to obtain before purchase? Let’s see the applications and the common components of truck scales first.

Basic purposes for truck scales

1. Trade settlement – main parameters are gross weight,tare weight and net weight

2. Nontrade settlement – Maximum capacity is the key parameter.

Truck scales almost have some common parts,and do weighing tasks through the interaction of all parts. Therefore the common components of truck scale are also critical for customers’ multiple applications like purchasing or selling goods,recording data,or other purposes,since it can determine the total cost and profit of the whole transaction,improve product quality and inventory management,etc.

Common Components of Truck Scale

1. Foundation

Truck scale can be installed in a foundation pit so that the surface of truck scale is as high as the surface of the surrounding ground. Truck scale can also be installed on the ground,truck can drive up or down scale through ramps. And concrete foundation will be used in either of installing methods.

2. Scale body

Scale body is the weighing platform for truck driving. This weighing platform is

usually composed of several weighing modules,which can be combined to acquire required length. Those modules can be steel structure,smooth or checkered plate upon customers’ request. The module can also be a concrete structure,the upper surface of the concrete structure is the driving surface for trucks.

truck scale weighing body

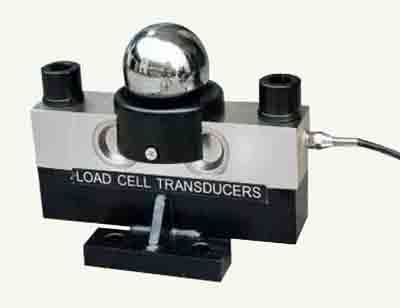

3. Load cells

Load cells are used for measuring weights,they are installed under each corner of the scale body,so scale body is supported by load cells. In this case the accuracy and reliability is important for the truck scale. Users can choose different brands load cells for their actual applications.

ZEMIC-HM9B load cell

Weighing indicator is the control part of truck scale. It displays weight data and connects with other outer devices.

5. Junction Box

Truck scales often take several junction boxes as joint points for loadcell cables. Junction boxes will gather signals of loadcells,and connect with weighing indicator through a signal cable finally. However,junction boxes are not necessary for all truck scale system. So electrical system in truck scale can be simplified without loadcells.

Junction box for load cells cables

6. Information Management

Now printing receipts has totally replaced traditional way of handwriting. Truck scale software plays an important role in whole system,like data can be collected automatically,speed up weighing process and reduce the error rate.

7. Accessories

Traffic control system,like railing machines and traffic lights,large screen displays are generally used in truck scale systems. Some special equipments,such as cameras and video card readers are also integrated into the system. In addition,modern automation and self-service functions can be offered in some truck scale sites.

So for above components, buyers should be familiar with their performances to determine the most suitable equipment they need.