Interface Technique of Weighing Terminal

Interface is a device that can exchange information or transfer signals. Therefore information exchange or signal transmission between two devices can reply on interface.

For better understanding Interface technique,let’s first have a look at signal.

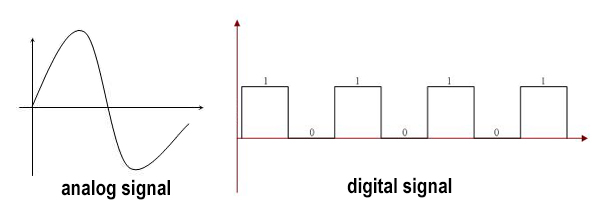

Signal serves for data transmission. In order to transmit data among different equipment,various data must be converted into signals. It can be classified as analog signal and digital signal. Analog signal always keeps continuous variation with time,like voltage signal or electricity signal. Digital signal,unlike analog signal,which is described as a series of discrete electrical pulses or optical pulses. Picture showing as below:

Different signals match with different interfaces. Corresponding to signal types, one kind of interface is analog interface to transfer analog signal; and the other one is digital interface for exchanging digital information, examples like “high” or “low” in signal level respectively indicates “1” or “0” , and the “connection” or “break” in electricity represents “1” or “0” as well.

How is the data transmitted? Especially for digital interface mode.

1. Two transmission modes:

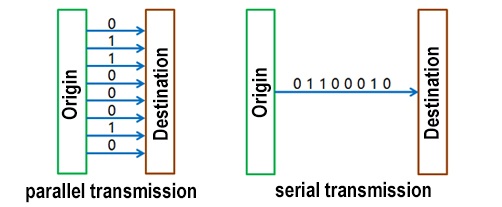

1) Parallel transmission: Multiple bits are transferred from the origin to destination on parallel transmission lines. For instance, one byte is comprised of 8 bits, then 8 bits are transferred synchronously on eight lines. And bytes are transferred one bye one in serial mode. Many weighing terminals output data to printer through parallel transmission.

2) Serial transmission refers to transferring 8 bits datum one bye one on a single transmission line sequentially.

Comparing two ways above,parallel mode can transmit data fast,but the transmission distance is short; on the contrary,the transmission speed of serial mode is slow,while the distance is long. Now serial transmission mode is primarily applied.

2. Three interfaces of serial transmission:

1) One-way interface: transmit data in one direction

2) Half-duplex interface: transmit or receive data in bi-direction at different times,and transmission or reception can’t be implemented synchronously.

3) Full-duplex interface: transmit or receive data in bi-direction,and transmission and reception can be implemented simultaneously.

For weighing terminal,the most commonly used digital interfaces are RS232C,RS485,RS422,and 20mA electric current loop.

1. RS232C is a standard interface for serial transmission developed by EIA.

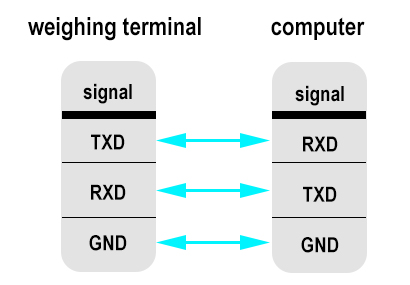

* In the communication between computer and weighing terminal,the simplest full-duplex system only uses three signal lines respectively worked as “send data”,”receive date” and “signal ground”. Usually 9-pin connector is applied and transmission line uses shielded twisted pair.

* For computer interface RS232C,the most commonly used signal lines are TXD(send data),RXD(receiver data),GND(signal ground). Through RS232C,weighing terminal connects with computer.

* Since the standard of RS232C interface appeared earlier, some insufficient points have been presented.

– The signal level value of the interface is high.

– Low transmission speed

– The interface uses a signal line and a signal return line to form a common ground transmission. This transmission is prone to generate disturbance when encounting similar signals, as a result, the noise immunity is weak.

– Transmission distance is short. The maximum standard distance is 50ft(15m).

In view of above points,some new interfaces standards were introduced,like RS485 and RS422.

2. Compared with RS232C, RS485 and RS422 interfaces improved the weak points:

1) The signal level is lower than RS232C;

2) Max. transmission speed is 10Mbps;

3) Great anti-interference ability;

4) Max. transmission distance is 2000ft(about 600m),actually it can be further.

Generally,four signal wires are needed in a full-duplex circuit composed of RS422 interface, and balanced twisted pair is adopted in RS422. However two signal wires are available for a half-duplex circuit consisted of RS485, and shielded twisted pair transmission is commonly used.

3. 20mA current loop is a kind of digital communication interface.

Unlike RS232C,it uses “ON” or “OFF” of electricity indicating “1” or “0”. For RS232C,”High” or “Low” of signal level indicates “1” or “0”. The transmission distance of 20mA current loop is 300m. Therefore compared with RS232C, the current loop interface has the excellent communication performance of long distance and fast speed. What’s more,it has strong anti-interference as well on industrial fields. Especially for industrial environment with serious noise and complicated situation,the strong anti-interference performance is obviously effective. And the signal attenuation is small for long distance transmission process, no further repeater or other equipment are needed. Through the current loop,the weighing terminal can connect with the screen.

Specific interface of weighing terminal

1. Preset value output

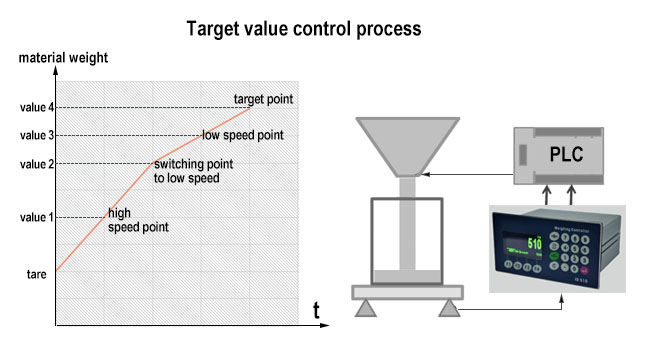

In order to achieve constant weighing purpose,weighing terminal can set a target value in advance. The output signal changes when the weight of the material on the scale reaches or exceeds the target value,and the subsequent devices are informed to respond this change. Here’s a example can clearly show the control process of preset value:

How to preset the target value upon the practical conditions?

a) Single speed is used when weighing one material, and set one target value.

b) Two speeds are used for one material,set two target values.

c) Multi-function weighing terminal can be applied in multiple materials and multiple speeds, multiple target values can be set.

2. 4~20mA analog output

The signal output by 4~20mA interface is the analog value keeping varying. In weighing industry,weighing terminal or weighing transmitter outputs 4~20mA, this analog output is used to indicate the weight signal. Usually,4mA stands for empty signal of the scale,and 20mA resprents full signal of the scale. For example, there is a scale with 300kg capacity, then 0kg is pointed out by 4mA and 200mA is for 300kg.

We have products with 4~20mA like: ID510 weighing controller,ID511 weighing controller,ID551 weighing controller,ID550 weighing controller.

Difference between 4~20mA and 20mA current loop is that transmitted signals are different.

a) Signals output by 4~20mA is the continuously varying value

b) Signals output by 20mA is the discrete value.

3. Fieldbus

Fieldbus is a kind of serial and digital data bus which can implement bi-direction communication in multiple points. It easily enables information transmission efficient as well as accurate between equipments in production field and auto-control system of the control room. Weighing controllers served as network nodes to perform information transmission via fieldbus.

I/O wiring mode is a traditional way of connection between field devices and weighing controllers,which can transmit 4~20mA or 24VDC signals. However for current fieldbus mode,the main feature is to replace 4~20mA or 24VDC with digital communication mode,using one cable to connect all field devices. And the considerable benefits are obvious:

1) Reduce hardware expense. Cost for cables,I/O module and cable laying engineering is largely lowered, and whole system cost is saved;

2) Easy for design,installment and test purpose;

3) Good reliability and safety. Less wiring points reduce faults;

4) Maintaining is a simple job,devices can be diagnosed online;

5) Complete the enterprise information system,it is beneficial to achieve comprehensive automation for enterprise.

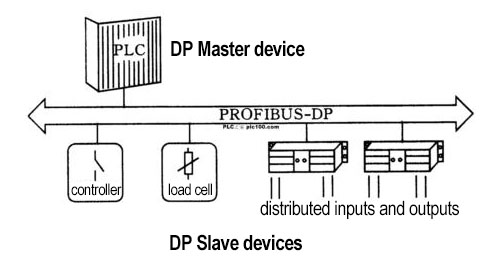

4. PROFIBUS-DP

Transmission with RS485 is the most commonly used technology for PROFIBUS-DP. Cable uses shielded twisted pair copper wire.

Three kinds of devices in PROFIBUS-DP system:

1) DPM1: The main station is central controller,it exchanges information with dispersed stations during a scheduled information period. Typical examples like PLC or PC.

2) DPM2: The main station is programmer,configuration equipment or operation panel, which is used to complete system operations and monitoring purpose when DP system is doing configuration operation.

3) DP slave stations are some peripheral equipments, such as weighing terminal,I/O device,driver,valve,and so on, they collect and transmit information of input and output.

PROFIBUS-DP is the system with single master station. Only one master station works when system is running.

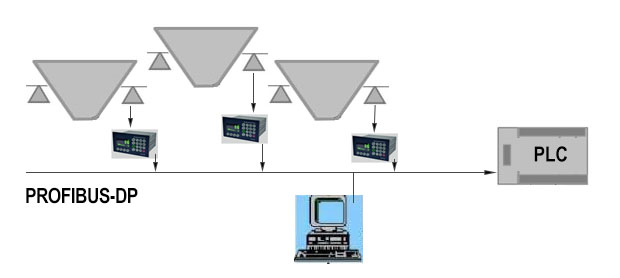

Below picture shows that weighing data of multiple material tanks is linked to the master station via a DP bus.

A configuration file(GSD file) is also involved in PROFIBUS-DP system. This document describes the features of each PROFIBUS-DP device. It includes parameters: baudrate,information length supported,the amount of input and output data,and meaning of diagnostic information.

PROFIBUS-DP requires to be set in weighing terminal. Here are some key points:

* Data format

– Is it integer,division number,extended integer,or floating point?

– How many scales will be contained? and how much data will be involved?

– Is data described in the standard format or a customized format?

* Node address that can be entered

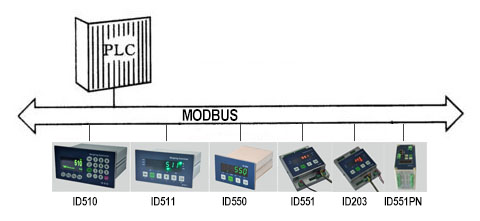

5. MODBUS

MODBUS protocol is a common language applied in controllers. Through this protocol,controller can communicate with each other,and communications between controllers and other devices via network are also available. It has become a common industrial standard.

This protocol gives a description of process that master controller requests to access other devices and how slave devices responds the requests. It also defines the message structure used by the controller.

If slave device responds with a message,then the message should contain information as following,

– The address of slave device to be accessed

– Response for function code of inquiry message

– Data section,contains data collected from secondary devices

– Error detection

ASCII and RTU are two transmission ways of MODBUS. Users can choose suitable mode upon their needs. At present,RTU is the popular mode for MODBUS protocol used in our weighing terminals. And some parameters should be set,including the address of slave device, baudrate, 8 digit data,no verification, generally use RS485 port.

Select a proper Interface is significant in weighing system

Now we can have a basic understanding of interface technology. Above text gives an account of different types of interface,how do they transfer data,and what are the advantages and disadvantages as well. Users should analyze practical situation,and select the right interface in accordance with actual application especially in weighing system.